-

двойная линия штранг-прессования трубы из волнистого листового металла стены

-

Одноместный гофрированная труба Экструзионные линии

-

линия экструзии труб HDPE

-

Линия штранг-прессования трубы ДВК

-

Линия штранг-прессования трубы PP

-

PVC Экструзионная линия для труб

-

спиральн линия штранг-прессования трубы

-

Линия штранг-прессования трубы предохранения от кабеля

-

Пластиковая труба Экструзионные линии

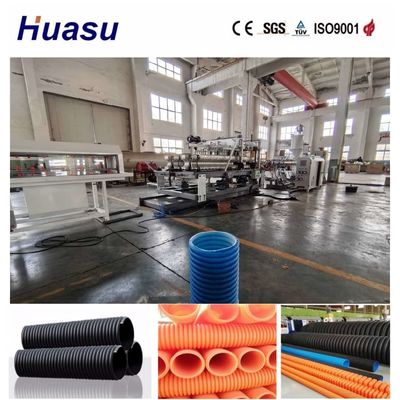

Get the Best Single Wall Corrugated Tube Extrusion Machine for PVC/PE/MPP/PA/HDPE Pipes at an Affordable

Свяжитесь со мной для бесплатных образцов и купонов.

Ватсап:0086 18588475571

WeChat: 0086 18588475571

Скайп: sales10@aixton.com

Если у вас есть какие-либо проблемы, мы предоставляем круглосуточную онлайн-помощь.

x| Layer | Single Wall ,Double Wall,Three Layer | Feature | High Productivity, Competitive Price, Energy Saving, Automatic |

|---|---|---|---|

| Engagement System | Full Intermeshing | Capacity | 60-2000kg/h |

| Pipe Diameter Range | 32mm-1600mm | Plastic Processed | PVC / PE / MPP / PA / HDPE |

| Application | Making Corrugated Pipe | Automation | Automatic And Computerized |

| Выделить | Single Wall Corrugated Tube Extrusion Machine,PVC PE MPP HDPE Pipe Extruder,Affordable Corrugated Pipe Extrusion Line |

||

Product Description:

The double wall corrugated pipe production line showcases the third generation of enhanced technology developed by Shandong HUASU. This latest model offers a significant improvement, boosting output and production speed by 20 to 40 percent compared to its predecessors.

Equipped with an advanced online belling function, the system ensures the finished corrugated pipes achieve superior quality and performance. Additionally, the entire operation is managed through a Siemens PLC control system, guaranteeing optimal efficiency throughout the manufacturing process.

Features:

We have developed a newly designed closed molding machine that integrates a specialized high-efficiency cooling system specifically for aluminum modules. This innovation ensures superior thermal management during the molding process, enhancing product quality and consistency.

Our high-speed, high-output single-screw extrusion machine is equipped with a professional corrugated pipe extrusion mold. This setup guarantees efficient production and precise shaping, making it ideal for demanding industrial applications.

Utilizing interchangeable LY12 high-quality alloy aviation aluminum modules containing 5% copper content, the system offers excellent durability and performance. These modules can be easily swapped to accommodate different operational needs.

The modules are produced through a precision pressure casting process that ensures resistance to deformation and eliminates the occurrence of light pores. This results in consistently robust and reliable components.

We also provide customizable waveform solutions tailored to meet specific customer requirements, allowing for greater flexibility and application versatility.

Additionally, the equipment features a computer-controlled automatic DWC cutter, delivering precise positioning and stable operation to maintain high standards in production accuracy.

Technical Parameters:

| Capacity | 60-2000kg/h |

| Feature | High Productivity, Competitive Price, Energy Saving, Automatic |

| Plastic Processed | PVC / PE / MPP / PA / HDPE |

| Engagement System | Full Intermeshing |

| Layer | Single Wall, Double Wall, Three Layer |

| Automation | Automatic And Computerized |

| Application | Making Corrugated Pipe (Drainage Corrugated pipe making machine, Single Wall Corrugated Conduit Production Equipment, Single Wall Corrugated Pipe Extrusion System) |

| Pipe Diameter Range | 32mm-1600mm |

| Control | PLC With Remote Control |

Applications:

This plastic pipe making machine is designed to manufacture high-quality pipes suitable for various applications. It ensures the production of durable and reliable pipes that cater to different needs.

The pipes produced by this machine are ideal for water supply systems, providing a safe and efficient solution for transporting potable water. Additionally, they are widely used in drainage systems to effectively manage wastewater and prevent blockages.

Moreover, these pipes serve as excellent conduits for electrical cables, offering protection and insulation to wiring installations. The manufactured pipes comply with industry standards, guaranteeing strong performance and long-lasting durability even in demanding environments.